Company profile :

Mingsanfeng Cap Mould Co.,Ltd founded in June 1999, the company specialises in development ,production,sales and service in plastic caps injection. The factory also has mould workshop, which has rich experience in R & D and production of plastic cap mould, and can customize all kinds of bottle caps. The company has nearly 60 employees, including about 10 engineers, 20 senior mold engineers and 30 senior technicians.

The company adopts modern management mode, with an annual output value of 35 million.Henceforth ,we shall be dedicated to be a “One Stop Service Provider” for the service and product ranging from mold design, mold manufacturing, injection processing, assembly and after sales.

Specific business

Mingsanfeng Cap Mould Co.,Ltd founded in June 1999,the company specialises in development ,production,sales and service in plastic caps injection. With all kinds of flip top caps,disc top caps,unscrew caps,security engineer-oil caps,washing liquid covers,cosmetic jar bodies and caps etc. The products are used in washing products, cosmetics, food packaging, medical supplies, packaging, etc.

The factory also has mould workshop, which has rich experience in R & D and production of plastic cap mould, and can customize all kinds of bottle caps. The company has nearly 60 employees, including about 10 engineers, 20 senior mold engineers and 30 senior technicians. The company adopts modern management mode, with an annual output value of 35 million.

Our strengths

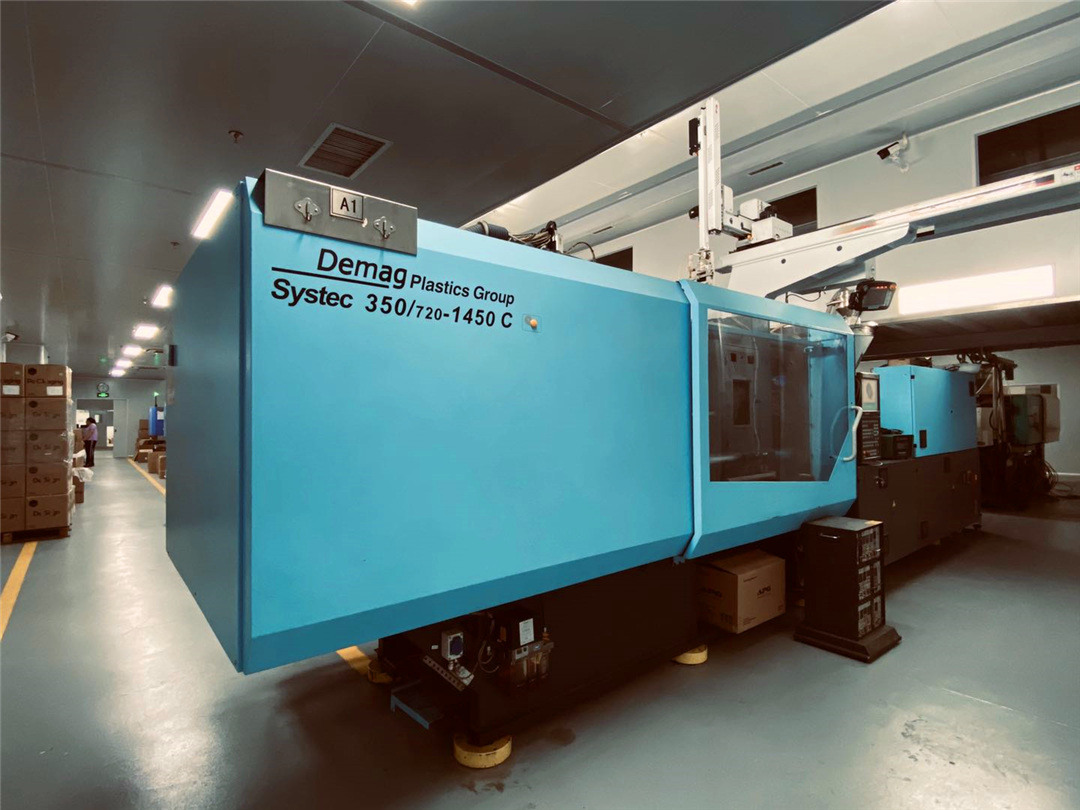

The company has advanced production equipment and automatic assembly equipment with GMP injection workshop. Total 20 sets 100-350T imported injection machines include Japan Toshiba, JSW , Germany Demag . It has a rapid prototyping mold and hot runner system mold with In Mould Closing(IMC). We can undertake all kinds of difficulty, high-precision molds and special injection products for international high-end customers. Specialize in designing and processing production of various bottle cap products . The research and development of mold equipment are Yasda, Okuma, OKK, Hatting and Japan Longze. The detection equipment includes Three-dimensional Zeiss and Two-dimensional. Henceforth ,we shall be dedicated to be a “One Stop Service Provider” for the service and product ranging from mold design, mold manufacturing, injection processing, assembly and after sales.